In-house testing – longitudinal mooring winch for immersed tunnel

In-house Testing – Longitudinal Mooring Winch for Immersed Tunnel

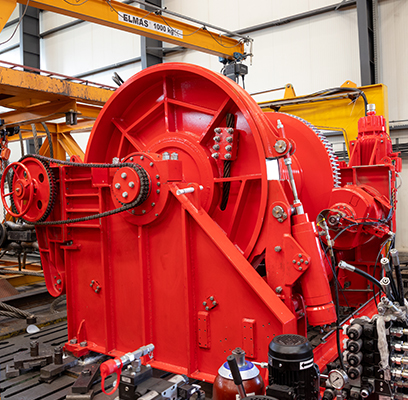

Placed on the deck of the base float, the longitudinal mooring winches, 4 in total, will be responsible for positioning the tunnel element in a longitudinal direction during the immersion process.

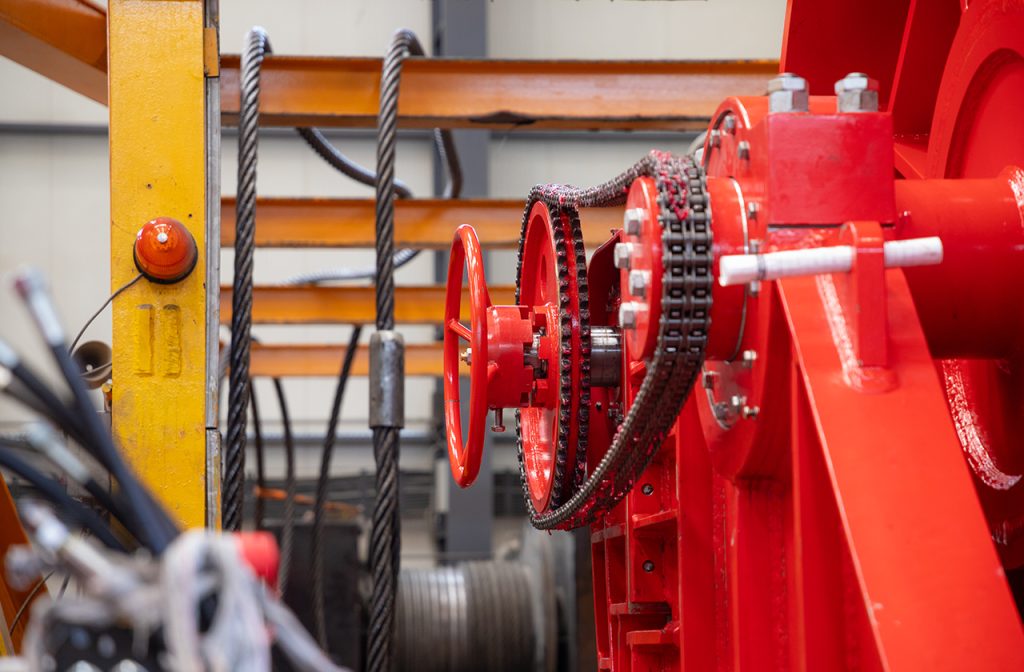

With three electric motors and three angled planetary gearboxes, these winches are also equipped with a device that detects the last three windings on the first layer.

Regarding the technical performances, this type of longitudinal mooring winch generates a nominal pull of 900 kN on the 4th layer and a storage capacity of 600m in 6 layers for a Ø52 mm steel wire rope.

The longitudinal mooring winches, along with eight other types of winches, 66 in total, will be responsible for assembling the parts of the longest immersed tunnel in the world.